SANITATION

There are many different ways and recipes for making bar soap, but the basic ingredients are lye and lard. Most people who make soap now use regular Red Devil Lye and any type of lard or fat, There are still people who make bar soap using lye water, and the ability to make soap from lye water could be very beneficial in the future.

CAUTION: LYE (Sodium Hydroxide) is caustic, corrosive, causes severe burns, and can be fatal if swallowed. Keep lye away from eyes, skin and mouth to avoid serious burns. Keep lye away from all contact with acids, children, pets, and husbands. If accidental contact occurs with skin, flush repeatedly with cold water. Yes, it is wise to have a healthy fear of lye or any caustic chemical. However, just remember that all the mothers before us have made soap using what was at hand. Women seemed to have survived to pass on the secret.

For purposes of ventilation plus the volume of the batch, the soap making process is best done outside over a kerosene cooker or wood stove in a canning kitchen. It requires a large kettle, cast iron if you have one. Under primitive conditions, a wash tub over a small camp fire will work. The stirring is hard work, so bending over the tub is less tiring if the kettle is elevated.

HOMEMADE SOAP WITH LYE WATER

This is not so much a scientific recipe as an art form, and only practice will make it perfect. Lye water is boiled in a large stainless steel or cast iron pot, then 10 pounds or so of lard is added slowly, all the time being stirred with a long wooden spoon or slat. Then more lye water is added and the stirring continues until it thickens about like syrup. The harder the lard and the thicker the boiled mixture becomes determines how hard the soap will become. The soap is then poured into an enameled pan or even a wooden tray with shallow sides (2 inches or so) and allowed to cool. As it cools it gets harder, and when it is hard enough to hold shape it is sliced into "bars." When cold, the hard bars can then be levered out of the pan or tray and used as with any bar soap.

There are many failures with this method due to the variable strength of the lye water, the type of ashes used (hardwood ashes make hard soap), and the type of fat available. But the failures are still soap - just not hard bar soap. The soft soap may still be used for dish washing, shampooing or general cleaning.

It used to be a badge of honor for housewives to be able to produce only hard bar soap, and soft soap was looked at with disdain. After several generations passed and almost no one made soap and therefore had no memory of the pride of their grandmothers in making hard bar soap, soft soap became socially acceptable and is now widely used in America. So don't worry about whether the soap will be really hard or not: that comes with practice.

HOMEMADE BAR SOAP USING COMMERCIAL LYE

This method cheats, using commercial lye and other ingredients to ensure that the end result is almost always hard. Perfume or scents may even be added to this formula if desired.

Ingredients:

Save fat drippings in quart jars. When you have three quarts, thoroughly clean it by boiling it in an equal amount of water. Place kettle in a cold place so the fat can firm up. Cut fat from kettle sides. Pour off water and waste. Scrape off excess wastes from bottom of the lard cake. Clean kettle and replace lard cake. Melt over low heat. Dissolve the lye in one (1) quart cold water and let stand until cool (when the lye dissolves it heats the water), then add to melted fat slowly. Stir constantly. Mix other ingredients together and add to first mixture. If desired, 1/4 cup of pine oil may be added at this time. Stir until the whole mixture is thick and honey colored. Pour into a pan lined with clean white cloth (getting fancy now!). Before the soap becomes hard, mark pieces into the desired size or form into balls. When hard, set the pieces in such a way that they may dry out completely.

The cooking process goes very quickly on this small batch of soap, but the lye, ammonia, pine oil, or even essential oils will give off fumes. If this soap is made in an indoor kitchen, the windows should be wide open and the house well ventilated. It is possible for the fumes to cause temporary allergy like symptoms, which is why even with a small batch it is better to make the soap outside.

Now, since you are the only one in the neighborhood who knows how to make soap, you will have a monopoly on this item in bartering for other things you need. Wrapped in nice pretty paper, you are guaranteed a high "price" in trade for your soap.

MAKING LYE WATER

The easiest method of making lye water is to drip water through wood ashes. Sounds real easy, but it is a bit more complicated than that. One method that combines new technology with old is to use a 10 foot length of plastic rain gutter, complete with a cap on one end and a down spout connection on the other end, and fasten it to fence posts about 4 feet off the ground. The down spout end should be about an inch lower than the capped end. Fill the gutter with an even layer of wood ashes, not tamped down or compacted. Water sprinkled on the ashes will filter out the lye and drip out the down spout end.

Under the down spout end of the rain gutter should be placed two plastic buckets. The bottom one collects the lye water, and should have a valve installed in the bottom to drain the lye water. The lid for the bottom bucket should have a half-dozen holes drilled in a circle about 6 inches from the middle of the lid, each hole being about ½" in diameter. The bucket above that should have matching holes drilled into the bottom, so any lye water will run out the bottom, through the holes in the lid below, and collect in the bottom bucket. Straw is packed tightly into the top bucket, with its lid holding down the straw. In the lid for the filter bucket, cut a hole that matches the down spout, and place a length of down spout between the rain gutter and the bucket.

What you now have is an automatic lye water machine. Because the system is "closed," rain water cannot dilute the lye solution, but rain can be used as the source of water for the ashes, so lye water can be made in the winter. During heavy winter rains, a board can be placed over all but the first foot or so of the gutter, which will limit the amount of water intake and still allow what rain falls into the first foot to filter through all of the ashes to the exit down spout.

The straw in the filter bucket acts exactly as a filter, removing any contaminants and purifying the lye water.

Remember that the composition of the wood ashes determines the quality of the lye produced. Soft wood ashes yield a lye that will only produce soft soap. Hardwood ash lye will make harder soap for bars, and the best ash of all is from seaweed, such as kelp. Kelp ash lye produces an extremely hard, durable soap. And here you thought the British fought the Falklands Island war over sheep! The finest kelp ash in the world comes from the sea around the Falklands.

Every part of the "automatic lye machine" listed above is made from plastic. Do not use any metal in the fabrication, particularly a reactive metal such as aluminum, as lye really is "caustic," and will quickly eat right through many metal containers.

Lye

water may

also be used for washing non-carpeted floors, followed by rinsing with

cold

clean water. The lye water will oxidize and sanitize the floor: any

bacteria or

insects will be killed. It can also be used to sanitize outhouses

and latrines.

Just be sure to wear rubber gloves and always use cold water to rinse,

as hot

water makes lye rather active.

This usually not thought of or dealt with subject must be covered thoroughly, as failure of the public water or sewer waste systems pose a very serious problem. Your home toilets will no longer flush! They might even back up into your bathroom from the sewer line running down your street. Improper disposal of human waste is a sure cause of disease, particularly cholera and typhus, and I want you to survive.

BROKEN SEWERS AND SEWAGE FLOODING

It doesn't take an earthquake or natural disaster to knock out the sewage system in the cities. If the electric power goes out, the pumping stations fail to operate. In the summer of 1999, one California city tried a Y2K test of its system, and the result was millions of gallons of raw sewage flowing through Balboa park. The worst danger, though, if that those homes on the lower ends of the sewage pipelines get all of the sewage flow: toilets back up, basements become flooded, entire subdivisions of homes rendered unlivable. There are two ways to prevent that problem: a one-way flap valve, or a gate valve, installed in the 3 or 4 inch main sewage line leading from the home. The flap valve is automatic, working simply by gravity. The gate valve requires that someone be there during an emergency, go into the crawl space or basement, and turn the valve shut. There are those who claim that the flap valve itself can become a sediment trap and cause a sewage flow problem, but that is a theoretical concern, whereas the threat of a sewage backup can be very real. Either type of valve can be installed by a plumber, or even by a semi skilled homeowner.

There are three stages in the disposal of sewage: emergency shelter living; semi-permanent toilets in the case of societal failures; and, more permanent latrines or toilet facilities.

PERMANENT TOILET FACILITIES

A permanent toilet facility will function independent from municipal utilities. Now you know why I emphasize a gravity flow water system and country living with an independent septic system. There isn't much that can go wrong with such a system, even if the electricity goes out. A few years ago we were at a New Year's eve party, and everyone got "sick" from something we ate. We left early (for obvious reasons), and as we were driving home a tree fell across power lines miles away and took out all the electricity (winter storms are common in the Pacific Maritime Northwest). A small flashlight got us safely into the house, kerosene lamps were lit, and I turned off one valve to isolate the well pipeline (to keep pressure in the system), then turned another valve "on" to open the gravity flow water system. In 5 minutes we were back in business with lights and running water. I placed some more wood in the wood stove, and soon we were warm. We were still sick, but we were comfortable in a warm, well lighted house, and the toilets worked as always.

When we got up in the morning, coffee was made and breakfast cooked on a kerosene cooker. At noon the electricity came back on, and I turned off the gravity flow system and opened the valve for the well system: because I had shut it off before the pressure dropped, I didn't have to go out in the rain and pressurize the tank again before it would work. There was virtually no inconvenience for us caused by the power outage.

Meanwhile, back at the house with the party, there were no lights except a few candle stubs and one (1) flashlight with half dead batteries, no running water, and there were a dozen people lined up to use a non functioning toilet. They did not have a happy New Year's Eve or New Year's Day!

Adapting your home with an alternative water system, kerosene lamps, plus food and other supplies means you don't have to worry about the small day to day emergencies that occur: you simply adapt and continue living under virtually normal conditions.

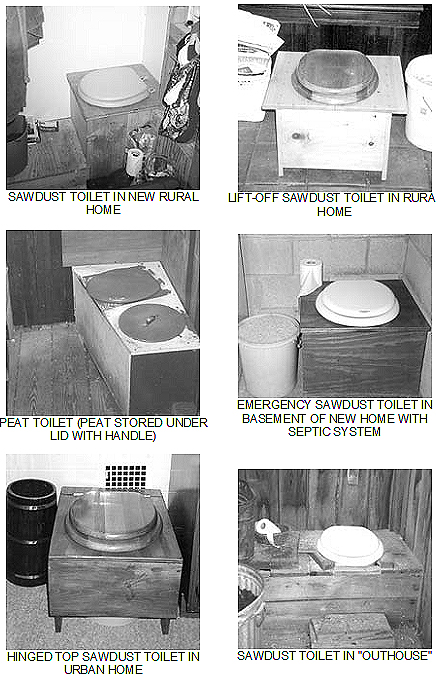

Those dependent upon public sewer systems may want to prepare in advance with a composting toilet: they work, and you can either build your own system or purchase a commercial unit quite inexpensively (Do a web search to see if what you find is fits your needs.). Homes with a working septic system but not a reliable, gravity flow water system will find the septic system does not work without the input of a lot of water through the toilets...they too could benefit from a composting toilet.

SEMI-PERMANENT TOILET FACILITIES

Now we are talking outhouses. Here a deep hole is dug, say 4 feet square and 8 feet deep, and a wooden building with a real door is built around the hole. The pit is partially planked over, with a box or platform bench in the back in which a hole is cut for sitting down. Outhouses must be ventilated, and window screens are a necessity. It is easy to forget proper sanitation rules with an outhouse, but they must be followed to ensure safe and healthy operation. There should be a hinged board which covers the hole in the bench, and it should be down when not in use. The toilet "seat" should be cleaned and disinfected at least once a day with a strong chlorine solution. Once a day, some lime should be thrown down the hole, which will help eliminate odors. Soap and water must be available, even if only in wash basins. If hand towels or linen must be used for sanitary purposes, a heavy plastic bucket with dilute lye water or bleach solution should be used for soaking clothes (similar to a baby's diaper pail), and the linens washed daily.

TEMPORARY TOILETS

In the military, these are called trench latrines, or straddle trenches. A foot wide, two foot deep trench is dug. Curtains of black plastic sheeting, canvas, bamboo and/or wood, or burlap can be erected to provide privacy, but normally no seating arrangements are provided. After use the material in the trench must be covered immediately with earth. Once a day the bottom of the trench should be covered with oil. Fuel oil, crude oil, used engine oil, diesel, kerosene, it doesn't matter, as they all act as a larvicide to control flies and other insects. When the trench is half full, it should be covered with soil, and then another trench dug.

EMERGENCY SHELTER LIVING

Nuclear fallout or a complete breakdown in societal conditions would necessitate living in a confined shelter for several weeks. The problem of sewage disposal must be undertaken in a careful manner. Perhaps the most expedient method is to have a portable toilet seat (the kind that has folding legs) placed over a 5 gallon bucket. The bucket should be lined with a tall kitchen trash bag, and closed between use. When the bag is partially full, it should be closed tightly with a twist tie and stored in a sturdy 15 gallon bucket or something similar that can be tightly closed. The reason, of course, is that the sewage must stay with you in the shelter until it is safe to come out. Then the entire large container must be carried outside and the contents placed in a deep pit, covered with lye or lime, then a layer of soil at least 2 feet deep shoveled over the entire thing.